3D Printing with Advanced Engineering Materials.

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material.

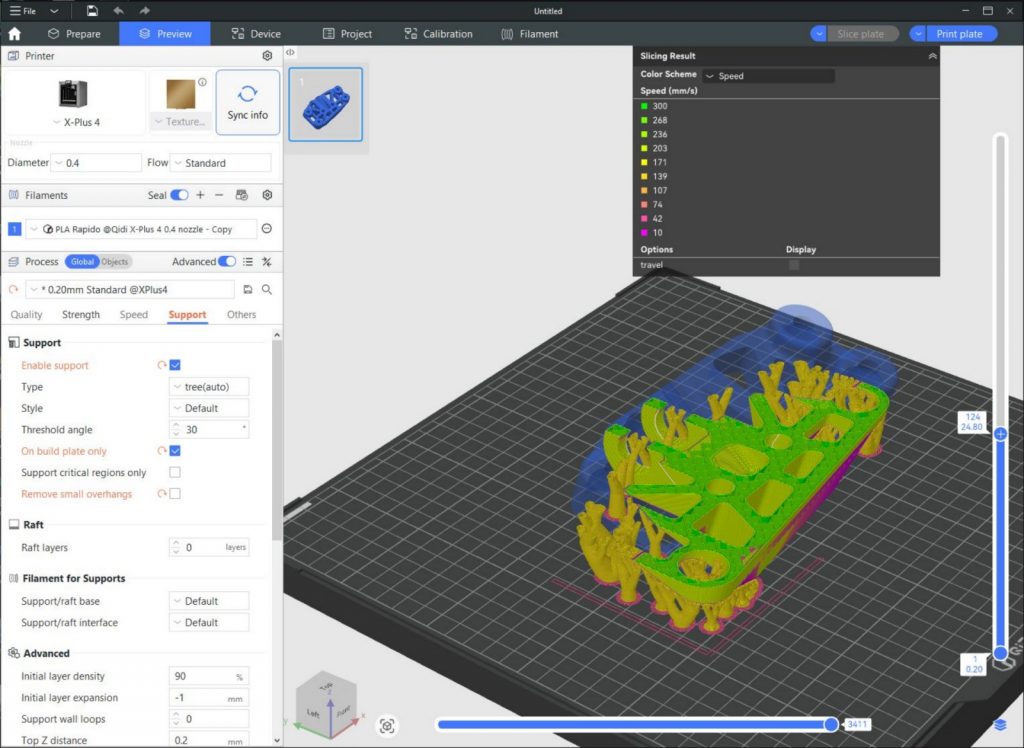

Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape.

FDM technology is trusted for its precision, reliability and repeatability. It is one of the easiest 3D printing technologies to learn and operate and is also extremely affordable. Material diversity opens your application space with capabilities bridging engineering-grade plastics to high-performance polymers.

Please visit our Resources page to learn more about the materials and their properties.

CAD (Computer-aided Design), CAE (Computer-aided Engineering and DFM (Design for manufacturing) services.

With decades of Product Design and Manufacturing experience in the Aerospace Industry we make it easy to bring your concepts to reality.

We can assist with 3D model creation, model preparation for FDM printing and Material selection based on intended application and budget.

We can also provide advanced Engineering Analysis services to validate your products intended purpose.

Our Approach

We will work with you to determine if FDM is right for you, and if it’s not we’ll tell you that and recommend an entirely different process.

1

Step One: Assessment

We begin by evaluating your current and future needs to recommend the best solution.

2

Step Two: Implementation

Our experts will work with your team to deliver timely results based on Step 1.

3

Step Three: Support

We provide ongoing support to help improve your products and deliver efficiency where we can.